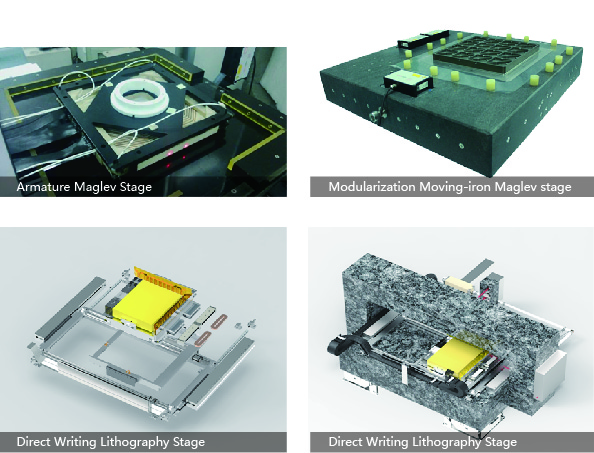

Advanced Customized Motion Stages

Advanced customized motion products use the electromagnetic drive technology to meet the requirement of the Nano level precise motion and the customization of object located stage.- Product introduction

- Product features

- Technical parameters

- Reference picture

Advanced customization motion stage is using electromagnetic driving technology to meet a kind of customized requirement - nanoscale ultra-precision motion and positioning. The application focus on the nanoscale to hundreds of nanoscale precision motion and positioning, for instance wafer detection, laser processing and laser etching etc.

From the view of equipment integration, we devote to accuracy analysis and disassemble policy providing a set of motion product structure and control design output solution as well as the seamless docking of the subunits to maximize the equipment terminal performance.

In accordance with the equipment

operating environment, we are able to develop a complete set of motion &

positioning control algorithm and calibration technology which has strong

robustness against the ground vibration, as well provide complete software

interface for control system and update service of secondary development.

The advanced customization motion products include linear motion and multidimensional motion stage, which applies high resolution laser interferometer as position feedback. The reliable control system based on VME bus protocol laid foundation of the nanoscale accuracy’s realization.

The motion stage

adopted planar motor structure which this driving technology was realized for

the first time domestically in 2009

Overall, the stage includes stator and mover part among which the former is coil array and the latter is permanent magnet array avoiding the external cable disturbance and guaranteeing the nanoscale precision positioning. X/Y direction applied the adjustable reflector for feedback measurement of laser interferometer. Through adjusting the reflector posture can satisfy orthogonality of the X/Y direction which overcome the lack of orthonolity in the traditional process. Water cooling part fixed on substrate of the coil array facilitate to control the temperature of the whole system.

Through years of research, optimization and reservation, we have formed a complete process of design, manufacturing and integration, and have applied in advanced mechanical and electrical fields like wafer checking, maskless lithography and laser process successfully.

|

|

Parameter |

Remark |

|

X/Y resolution |

1nm |

|

|

X/Y absolute positioning accuracy |

±5nm — ±100nm |

customizable according to requirement |

|

X/Y stroke |

±1mm — ±500mm |

|

|

acceleration |

0.1g —2g |

|

|

speed |

1mm/s — 1000mm/s |

|

|

payload |

0.1Kg —10Kg |

|

|

dimension |

50mm×50mm—300mm×300mm |

weixin qr code

weixin qr code